‘Tis the season

Innovative drilling

Lemken’s Solitair front hopper is the answer to the growing demand for efficient front-rear seeding combinations, according to the company. With a generous 2,400-litre capacity for seed and/or fertiliser, this pressure-resistant hopper is ideal for precision seeding or drilling, ensuring maximum utilisation in the field. Seed or fertiliser is delivered to the rear combination units either to the right or optionally underneath the tractor.

The front hopper is equipped with four modular dosing units with individual electric drives. If the Solitair F is used as a single hopper, it can optionally be combined with four width sections, for example with the Azurit precision seed drill for under-root fertilisation or with the OptiDisc 25 coulter bar. The new optimised OptiDisc coulter bar can now be used for single or double shot drilling, so when used in combination with the Solitair F double hopper, two components can be applied at the same time. Added value Optimum soil contact is one of the basic requirements for high crop yields. To achieve this, the Solitair F is additionally equipped with a front mounting section for attaching a large tyre packer or an external weight of up to 800kg. The optimal weight distribution of the front-rear combination ensures greater safety and a more comfortable ride. The steerable trailed tyre packer can also be mounted on its own as a front tyre packer and be ballasted with suitcase weights of up to 500kg. Lemken says the Solitair F front hopper combines versatility, efficiency and comfort, making it the ideal solution for professional farmers who want to maximise the utilisation of their implements.

Highly flexible seeding system

Horsch’s family of disc and tine-mounted drills can be combined with its Partner FT front tank to offer ‘highly flexible seeding system for all crops and conditions’, the company says. The 6m Sprinter 6 SL tine drill and 6m Avatar 6.25 SL disc drill, which were launched at Agritechnica, join a wide choice of Horsch mounted drill models to allow farmers to create a versatile seeding system that suits their needs. The Partner FT can be combined with seed drills, used for tillage for deep fertilisation, in hybrid farming or in combination with a Finer SL. Combining the drill with a Partner front tank optimises the weight distribution of the tractor and seeding rig.

The Avatar SL is the smallest and most manoeuvrable Avatar seed drill with a mounted three-point configuration designed for precise sowing in mulch seed conditions. The 6m SL mounted model reduces tillage to a minimum yet works well in high amounts of straw residue, and in harder soils. The depth control roller of the SingleDisc coulter ensures a regular depth placement even in uneven conditions. Row spacings of 25cm or 30cm pave the way for mechanical weed control. Hydraulic weight transfer achieves a coulter pressure of up to 240kg per coulter, with the weight of the tractor transferred to the seed coulters. This is useful especially in harder conditions and considerably extends the range of use of the machine. The Avatar SL is available with trash wheels that smoothly manage high amounts of straw. The trailed layout of the trash wheels allows for a perfect soil adaption as each trash wheel can be adapted individually to the desired depth and the soil is only minimally disrupted.

The 6m Sprinter 6.25 SL is ideal for working in wetter conditions and on light and medium soils. As it is mounted, it is high manoeuvrable making it easy to operate in small fields. The tines are hydraulically pre-stressed and retractable and are individually depth controlled with press wheel. The three-bar tine section and 25cm tine spacing ensures a straw-free and clod-free sowing horizon. There are different seed coulter options from the Ultra ThinEdge seed coulter, that provides a 12mm wide seed band to ensure minimum of soil movement, the ThinEdge coulter with a 21mm wide seed band (ideal for sowing catch crops directly into the stubble), to the WideEdge tine seed coulter that has a 110mm wide seed band.

New hydraulic folding model complements existing range

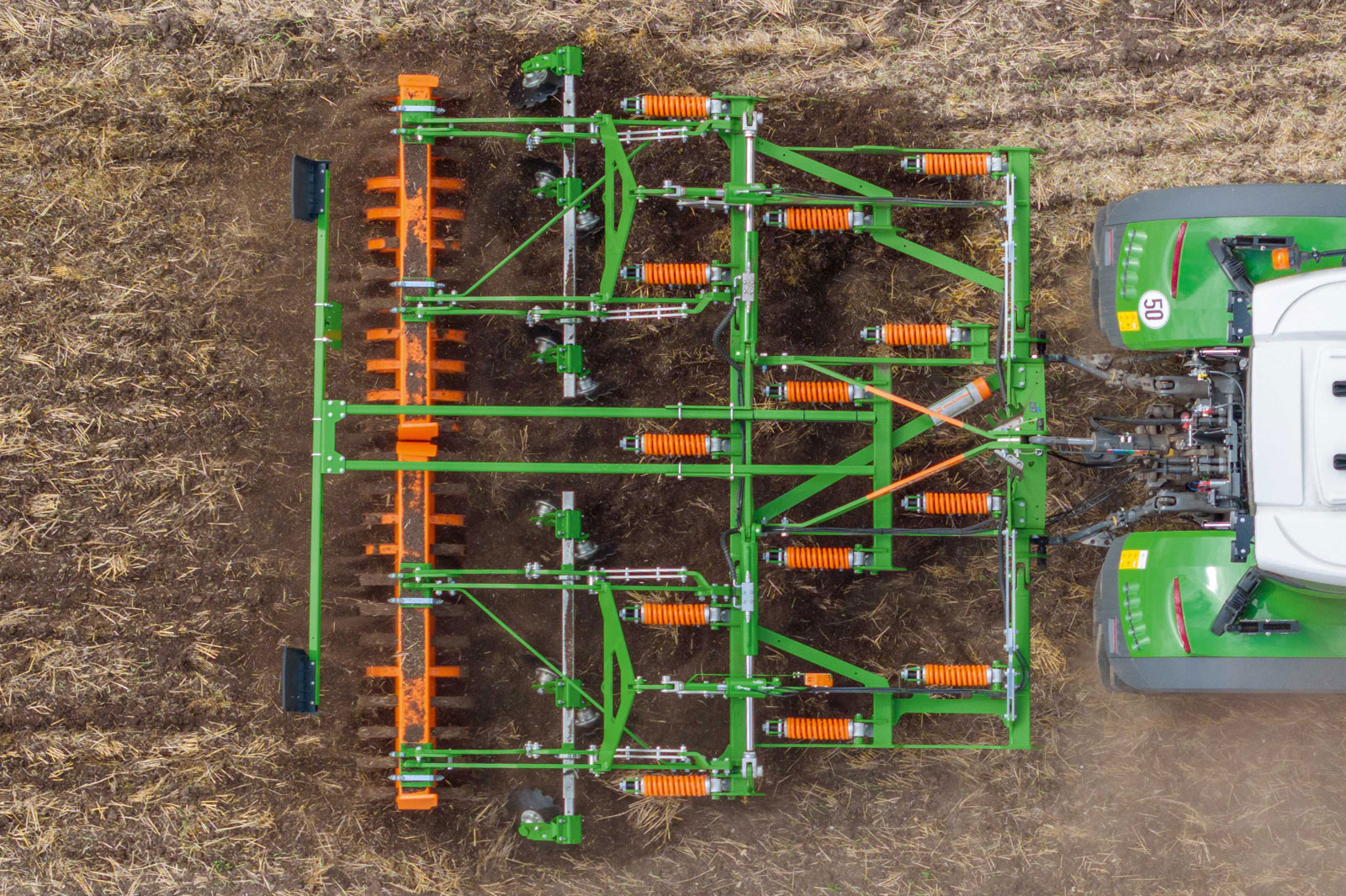

Amazone’s new Cenio 4000-2 is a folding mulch cultivator in a 4m working width, that can be used with tractors ranging from 105hp to 275hp. This new hydraulic-folding model complements the existing Cenio product range of 3m, 3.5m and 4m rigid machines, according to the company.

The three-point linkage mounted Cenio is a three-row mulch cultivator with interchangeable shares for depths from 5 to 30cm. This enables the cultivator to be used for both shallow stubble cultivation as well as medium-deep and deep-loosening soil tillage. With a tine spacing of 30cm the Cenio can work with large amounts of crop residue, evenly mixing the matter back into the soil without blockages.

The working depth of the Cenio 4000-2 is hydraulically adjusted from the tractor cab. The depth can be tailored to suit the field and soil conditions on the move and an easy-to-read scale is used for orientation.

Fine-serrated, 410mm diametre concave discs are available for levelling the soil behind the tines. With maintenance-free bearings, the discs have a high self-driving effect combined with good crumbling of the soil.

The automatic disc-levelling system means the height of the levelling unit is automatically adjusted via the parallelogram linkage when the working depth of the tines is changed. This ensures the levelling quality always remains the same, even when the working depth is changed, and the operator workload is further reduced.

There is a choice of seven rollers for re-consolidating the soil, ensuring the ideal roller for any operating condition is always available. In the event of widely varying fields on a farm, the roller can be exchanged with minimum effort thanks to the quick-change system. The rollers can also be supplemented by a optional single-row harrow system.

No-till seed drill offers great flexibility

Väderstad’s Seed Hawk 600-900C is a no-till seed drill is available in working widths of 6m, 8m and 9m and, according to the company, it offers farmers flexibility to adapt to different field sizes and soil conditions. Its standout feature, says Väderstad, is the tine coulter system, which creates a clean seed slot, placing both seed and fertiliser in undisturbed soil for optimal germination and growth. This precision is further complemented by its 7,000-litre pressurised hopper, which is divided into three compartments. This innovative design allows for the independent mixing and application of up to three products.

At the core of the Seed Hawk’s performance lies the Fenix III metering system, which handles the precise delivery of seed and fertiliser. The system’s advanced design enables section control to optimise input use. For example, the six-metre version operates in two sections, while the larger eight- and nine-metre machines are divided into three sections. This feature minimises overlaps, reduces input costs, and maximises field efficiency. Whether dealing with small seeds or larger fertiliser granules, the Fenix III system ensures consistent metering and application across the entire working width.

The heart of the Seed Hawk 600-900C lies in its individually mounted dual-knife tine coulters, which are designed to deliver unparalleled accuracy in all soil conditions. With a row spacing of 250mm, each tine coulter is paired with a packer wheel that ensures consistent seed depth and excellent soil-to-seed contact. This precision is enhanced by the hydraulic coulter downforce system, which provides up to 190kg of adjustable pressure. Operators can fine-tune the downforce directly from the cab using the E-Control system, adapting the machine to varying soil types and conditions with ease. Additionally, the fertiliser is placed 38mm offset from the seed row, creating an ideal environment for early root development and maximising the crop’s yield potential. For those requiring additional adaptability, the Seed Hawk offers an optional front disc system. This feature enhances the machine’s performance by combining the benefits of a disc coulter with the microclimate created by the dual-knife tine coulters. The front disc ensures a clean and even seed slot, further improving seed placement accuracy. By integrating this system, farmers can achieve the best of both worlds: the precision of a disc coulter and the reliability of a tine coulter.

Another critical component is the press wheel, which plays a key role in sealing moisture into the fertiliser row and preventing soil capping over the seed. Positioned directly behind the knife coulters, the press wheel operates in the tilled soil, maintaining consistent seed depth while ensuring smooth and precise operation. This design significantly enhances seed-to-soil contact, which is critical for uniform germination and robust early growth.