Anaerobic digestion: A slow burn

Given the fact that the technology is tried and proven in Northern Ireland, the UK, across Europe, and globally for many years, there is little justification for the inordinate delays in progressing the development of biogas production. And, yet, lack of progress is what we have. Even when the Government finally publishes its support measures for developing a viable AD industry, the planning system, complete with opportunities to stymy developments indefinitely, means that, even if the Government intervention provides adequate encouragement for progress, the rate of that progress will be far too slow to meet any targets set, either in terms of timelines or scale. From a farmer perspective the optimal model for agricultural AD in Ireland will be centralised plants, with several farms in the catchment area supplying the feedstocks.

International comparison

Other countries in Europe have developed successful AD industries. Almost 40 per cent of Denmark’s gas consumption comes from biomethane, with a national ambition to increase biomethane production to substitute 100 per cent of Danish gas demand before 2030. Most of Denmark’s biogas is produced from farm manure. Closer to home there are 80 AD plants in Northern Ireland, which mostly use agricultural feedstocks, including silage. In addition, there is a food-waste stream from the Republic being transported to NI for use as a feedstock in biodigesters there. In Denmark, Northern Ireland, and elsewhere across Europe, biogas has been promoted through public financial support.

Teagasc AD model

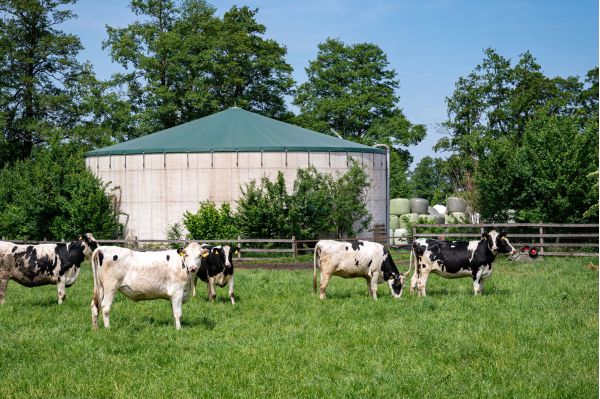

Teagasc has progressed the development of a pilot AD plant at its Grange Research Centre to final pre-production stage, with full commissioning and production expected in the coming months. The digester consists of a 1,600m3 concrete tank fitted with external insulation protected by steel cladding. The tank is covered by a gas-tight membrane on top. The unit will, at least, provide an example of what is involved for anyone interested in developing a biogas production facility. The Grange plant is being constructed on a relatively small scale. To reach the national target of 5.7TWh of biomethane by 2030, at least one 150 large-scale AD plants will have to be constructed. These plants will require scale with an annual capacity of at least 40GWh. For comparison, the Teagasc Grange AD plant will have an annual capacity of 3GWh. The Grange unit is calculated to produce in the region of 75m3 of gas per hour, with a target of operating for at least 8,000 hours per year. That would put annualised gas production at 560,000m3. Translating that into actual energy equivalent gives a calorific value of 22 Megajoules (Mj) per cubic metre, which equates to six kilowatt hours per cubic metre. Using those figures per cubic metre of gas produced across annualised production targets indicates a yearly output rate from the plant of 12.3 million Mj or 3.4 million kWh. It should be noted that up to one quarter of the production is required for processing the energy. The figures above provide the raw data. Further processing of the gas into biomethane enhances the heat equivalent value up to 45Mj per cubic metre. The digester will be fed with a mix of slurry and silage, the mix varying across the year, depending on raw feed availability. Winter slurry from 1,000 animals on the Grange farm will be used, as well as grass silage at 25 per cent dry matter, from 70 hectares. Greater efficiencies in the operation of the pilot AD plant including shorter retention and gas collection timescales should be able to deliver a third more biogas per hour.

Energy unit terms explained

Terawatt hours, abbreviated as TWh, is a unit of energy representing one trillion watt hours. A kilowatt hour is equivalent to a steady power of one kilowatt running for one hour and is equivalent to 3.6 million joules or 3.6 Megajoules (Mj).

Gigawatt hours, abbreviated as GWh, is a unit of energy representing one billion (1,000,000,000) watt hours and is equivalent to one million kilowatt hours.

Source: https://ec.europa.eu/eurostat/statistics-explained

Commercial viability

This would be some way off the output figures being secured on average from most biodigester units across Europe. Scale and output are critical to ensuring commercial viability of biodigester plants, with the reality that the competitive benchmark is with the price of natural gas. We can argue about the validity of this comparison, given that, like coal and oil, natural gas is already semi-processed when it is pumped out of the ground and the major costs are in further refining and transport for end use. Nevertheless, this is the commercial reality in which the nascent Irish AD industry must operate. The development of AD plants internationally was not achieved without the use of public money for the public good. In order to secure some degree of energy security in relation to gas needs, countries like Germany invested in indigenous gas production, even though the alternative was considerably cheaper and did not require public subvention. The full realisation of the benefits of that policy only became fully clear when Russia began using its gas supply lines to the West as a bargaining chip in its aggressive territorial expansion ambitions that saw Crimea subsumed in 2014 and the military annexation of Ukraine still being pursued aggressively.

A critical need

For Ireland, the necessity of replacing at least ten percent of imported natural gas with domestically produced biomethane is critical. Apart from the fact that we are at the end of an unreliable gas pipeline through the UK, our indigenous gas resource from the Corrib Gas Field is already well past peak production. We have, for ideological reasons, curbed, in fact banned, further gas exploration, most notable in relation to a potentially huge gas field off Barryroe. Neither do we have port facilities for large scale storage of imported natural gas, with belated realisation of this weakness being reflected in the proposed development of inadequate storage facilities that will not be available for some time, if ever.